Wrapping bales of hay: How to protect and preserve every bale

Meta description: Master wrapping bales of hay to lock in nutrients, stop mold, and safeguard every bale for year-round selling confidence and top value.

Preface

Are you a hay producer looking to protect your harvest, preserve its value, and sell confidently year-round? Weather shifts, poor wrapping, or cheap silage films can undo a season’s worth of effort. Hay spoils faster if left unprotected. It doesn’t wait. It absorbs moisture, changes color, and even spoils before you can sell it! But with proper wrapping, this shouldn’t worry you. This guide shows you how to wrap hay the right way so every bale you sell is worth top dollar.

Why wrap bales of hay?

Wrapping hay bales is more than a preservation step. It is a business decision that protects quality and profit, and builds your reputation as a dependable hay supplier. Here’s why you should wrap your hay bales for sale:

- Preserve hay quality: Proper wrapping extends hay’s lifespan, keeping it fresh, dry, and market-ready for months.

- Protect from weather: Shields every bale from rain, dew, and ground moisture that cause rot and spoilage.

- Prevent mold and nutrient loss: Airtight wrapping locks out oxygen and moisture, preserving protein, color, and feed value.

- Support livestock nutrition: Fermented silage bales stay rich in energy and are easier to digest, improving animal performance.

- Cost-effective storage: A good wrap is far cheaper than building barns or sheds while offering year-round protection.

- Ensure safe transport: Wrapped bales stay tight, clean, and easier to handle, reducing tearing and waste during transport.

- Boost sales and reputation: Clean, well-wrapped bales build buyer trust, reduce rejections, and reinforce your image as a quality producer.

Types of bale wrapping

There are several ways to wrap hay bales, each suited to different needs, crops, and budgets. The right method helps protect quality, speed up operations, and ensure better returns.

- Bale net wrap

Net wrap is the most efficient and popular option for both dry hay and silage hay. It forms a smooth, even layer around the bale, reducing moisture entry and cutting wrapping time by up to 50% compared to twine. Net-wrapped bales shed water better, keep their shape, and handle transport more safely.

- Silage film or bale wrap film

Silage wrap is a stretchable plastic film designed to seal out oxygen and lock in moisture, allowing fermentation to occur inside the bale. This makes it ideal for producing high-quality silage or haylage. It offers excellent protection against both UV rays and harsh weather, keeping bales fresh and nutrient-rich for longer storage periods.

- Twine wrapping

Twine is the traditional method of securing hay bales. While inexpensive, it’s slower and less protective than net wrap or film. Twine allows more exposure to air and moisture, increasing the risk of spoilage, especially in humid regions. It’s best for short-term storage or small operations where speed and long-term preservation aren’t top priorities.

How to choose the best wrapping for bales of hay

Choosing the right wrapping for your hay bales affects your earnings, losses, and how your product is perceived in the market. Consider these to keep every bale in top condition from the field to the buyer:

- Type of hay (dry vs silage)

Dry hay needs to breathe a little to stay crisp, so bale net wrap or twine works well. It holds the bale tight, reduces leaf loss, and makes handling easier. Silage hay, on the other hand, needs to stay airtight to preserve nutrients and maintain proper fermentation. That’s where bale wrap film comes in. It seals out air and moisture completely, locking in freshness and feed value.

- Local climate (humidity, UV exposure, rainfall)

In humid or rainy regions, moisture is your biggest enemy. Too much exposure leads to mold, fermentation, and nutrient loss. A strong bale wrap film or net wrap with high puncture resistance and UV protection keeps your hay dry and fresh longer. If you are in a hot, sunny area, choose a wrap designed to resist UV damage. Extended UV exposure can weaken the plastic and reduce protection over time.

- Storage duration and handling frequency

Long-term storage or frequent handling calls for tough, multi-layer wrapping that can handle stacking, movement, and exposure. If you plan to sell or transport bales quickly, lighter wrap may be enough. Consider where and how the hay will be stored: outdoors, in a shed, or under tarps. It affects how much protection your wrap needs to provide.

How to wrap bales of hay efficiently

Wrapping hay efficiently keeps your bales protected, nutritious, and market-ready. Every step matters, so follow these key steps to get the best results:

Step 1: Time right

Wrap your bales as soon as possible after baling, ideally within two hours. The longer you wait, the more moisture and oxygen seep in, causing mold and nutrient loss. Fast wrapping locks in freshness and prevents spoilage.

Step 2: Use correct tension and overlap

Start with a net wrap to hold the bale firmly together and create a smooth surface. Then apply your film wrap with the right tension and overlap, about 50% is ideal. This ensures an airtight seal without tearing or wasting material.

Step 3: Inspect wrap quality

Before wrapping, check your film for holes, tears, or sun damage. Damaged film compromises protection and allows air to sneak in. Always use fresh, high-quality wrap to get consistent results and longer storage life.

Step 4: Store bales properly

Once wrapped, store bales on a clean, dry surface: gravel, pallets, or plastic sheeting work best. Avoid wet soil or grass, which can puncture the wrap or cause moisture buildup underneath. Stack bales carefully and keep them out of direct sunlight for lasting protection.

Common mistakes to avoid when wrapping hay bales

Avoiding small bale wrapping mistakes can save you from major losses in hay quality and profit. Even experienced hay producers sometimes overlook these key details:

# Using low-quality wrap or old stock

Cheap or expired film weakens quickly, especially under UV exposure. It can tear during wrapping or storage, letting air and moisture in. Always invest in premium wrap, which maintains elasticity, tack, and strength even after long storage periods. Also, incorporate net wraps for added strength and to maintain shape.

# Wrapping too loosely or too late after baling

Timing and tension are everything. Wrapping bales hours after baling traps excess air and allows heating or mold growth. Loose wrapping fails to form an airtight seal. For best results, wrap within two hours of baling using tight tension and consistent overlap.

# Ignoring climate conditions when choosing wrap type

Your local environment affects wrap performance. In hot, sunny regions, UV-resistant film is essential. In humid or rainy areas, thicker, multilayer films prevent water penetration. Always match your wrap’s properties to your local climate to ensure lasting protection.

# Storing bales directly on soil or under direct sunlight

Ground moisture and sharp debris can puncture wraps or cause uneven fermentation. Direct sunlight accelerates film degradation. Use a gravel base, wooden pallets, or plastic sheeting, and store bales under shade or a tarp for long-term preservation.

When to wrap hay bales

The perfect time to wrap your hay bales is usually within the first two hours of harvest or as soon as possible. For silage bales, early wrapping preserves moisture and supports fermentation, and delaying may lead to spoilage. Net wrap should be applied immediately to keep bales firm and airtight. Twine wrapping, though cheaper, should only be used when hay is fully dry and there’s stable weather. Generally, to get the timing right for hay wrapping, monitor field moisture and weather forecast closely. If humidity is high or rain is expected, prioritize wrapping immediately to seal freshness and prevent mold buildup.

Is it worth it to use hay wrap nets for silage?

Yes, hay wrap nets are worth it for silage when you use the right material and correct wrapping methods. Silage, which is moist fermented fodder, needs airtight protection to support proper fermentation and prevent mold. Net wraps offer firm compression and faster baling, while film wraps add the final oxygen seal. Together, they reduce spoilage, extend storage life, and preserve feed quality. Net wraps can also be used on dry hay for easy handling. For hay sellers, this means higher resale value and fewer losses during transport or storage.

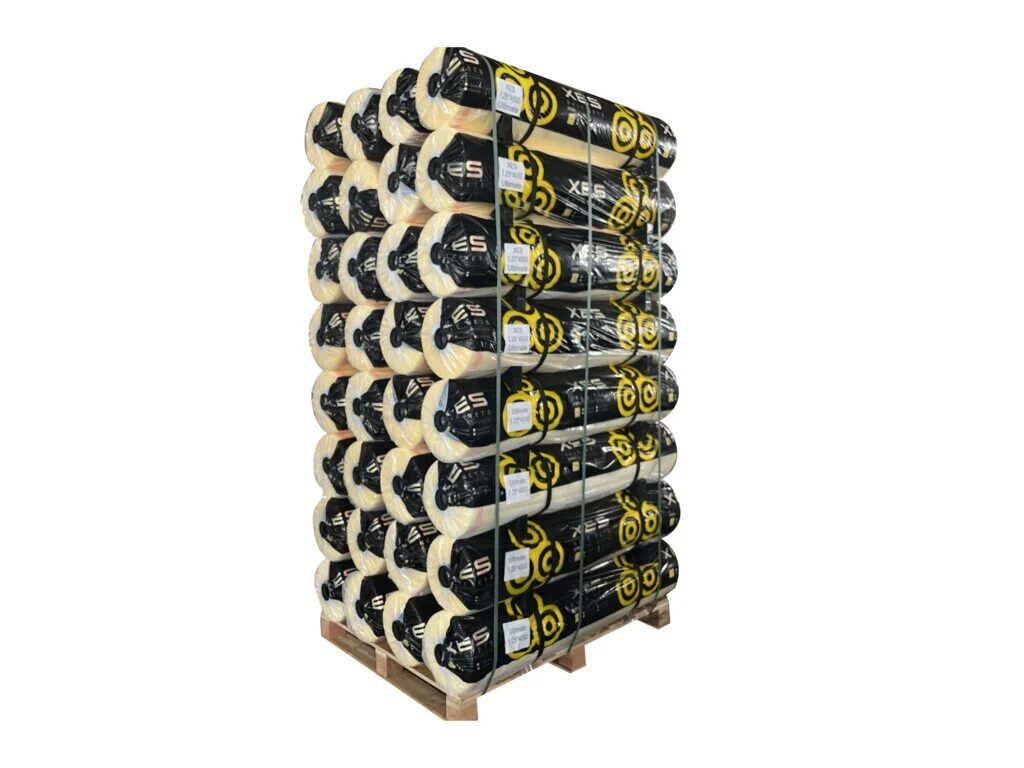

Wrapping nets wholesale for your hay bales

Are you looking for wrapping nets that can deliver clean, tight, and reliable bales season after season? XES Bale Net Wrap offers premium solutions trusted by hay producers, sellers, farms, distributors, and cooperatives globally. Each net roll is built to perform flawlessly with modern balers, protect your hay from weather damage, and keep your packaging process efficient. They are durable and UV-resistant, and designed to cut downtime and waste.

- XES® Classic Bale Net Wrap

The XES® Classic Bale Net Wrap is a trusted, all-purpose option for farmers who value reliability and ease of use. Made from eco-friendly HDPE with a tensile strength of 270 kg, it performs consistently across all baling conditions while ensuring long-lasting protection for hay, straw, or silage.

Key features

- Durable structure: The knitted chain design with reinforced threads adds strength and reduces film waste.

- Universal fit: Compatible with popular round baler brands like John Deere, New Holland, and Vermeer.

- Extra roll length: Each roll includes an additional 150 feet to ensure full value and consistent coverage.

- Color markings: Side color indicators and a red end-of-roll signal make it easy to monitor wrapping progress.

- Even winding: Smooth, precise rolling ensures uniform coverage and fewer handling issues.

Best for: Dry hay, straw, and silage.

- XES® Extreme Bale Net Wrap

Designed for demanding baling jobs, the XES® Extreme Bale Net Wrap offers high performance under pressure. DLG-certified for strength and reliability, it’s built from premium HDPE that resists UV damage and maintains a tight hold on heavy crops like silage and maize.

Key features

- DLG-certified quality: Tested and approved for strength and consistency by the German Agricultural Society.

- Reinforced build: Handles dense and heavy materials without tearing or slipping.

- UV protection: 12-month UV resistance allows safe outdoor storage.

- Easy identification: Side color markings and a red end-of-roll indicator streamline operation.

- Eco-conscious design: Made from recyclable HDPE that’s tough yet sustainable.

Best for: Silage, hay, and other heavy materials.

- XES® Supreme Bale Net Wrap

The XES® Supreme Bale Net Wrap is our most advanced option, built for professional operations that demand speed, strength, and precision. Its patented non-woven design reduces friction inside balers, while its 300 kg tensile strength and 5,000-meter roll length deliver outstanding efficiency.

Key features

- Patented non-woven design: Smooth surface reduces friction and tearing during wrapping.

- High tensile strength: Withstands up to 300 kg, ideal for heavy crops like corn and sugar beet pulp.

- Extended roll length: Up to 5,000 meters per roll means fewer roll changes and less downtime.

- Certified production: Manufactured under DIN EN ISO 9001 for consistent quality.

- UV stability: Made from recyclable HDPE with 12-month UV protection for long-lasting performance.

Best for: Silage, dense hay, corn, and strong straw.

FAQ

- Why do farmers wrap their hay bales?

Farmers wrap hay bales to protect them from moisture, mold, and nutrient loss. Wrapping keeps the hay fresh, improves feed quality, and reduces waste during storage or transport. For sellers, it also means fewer rejected bales and better market value. Using high-quality net wraps like XES® Bale Net Wraps ensures each bale is tightly sealed, weatherproof, and ready for long-term storage or shipment.

- How long do wrapped hay bales last?

Properly wrapped hay bales can last 12 to 24 months, depending on the wrap quality, climate, and storage conditions. The key is airtight sealing and UV protection to prevent spoilage. XES® Extreme and XES® Supreme Bale Net Wraps both offer at least 12 months of UV resistance and reliable durability. This gives hay sellers the confidence to store and transport their bales safely through multiple seasons.

- What’s the difference between net wrap and film wrap?

Net wrap is a woven plastic mesh that holds the bale together quickly and firmly, while film wrap is a stretchable plastic layer that provides airtight sealing, especially useful for silage. Net wrap speeds up baling and protects the structure, while film wrap preserves moisture and supports fermentation. Many farmers use both for maximum protection, pairing XES® net wraps with silage film for strong, weatherproof results.

- How many rounds of net wraps should be on one bale of hay?

Typically, 2 to 2.5 rotations of net wrap are enough to secure a round bale. However, heavier or looser crops may require an extra half rotation for added strength. The goal is full coverage without overusing material. With XES® Bale Net Wraps, each roll is precisely measured and evenly wound, helping you achieve perfect coverage every time with minimal waste.

- Why the color matters when wrapping hay bales?

Color plays a role in both identification and performance. Light-colored wraps, such as white or light green, reflect sunlight and keep the bale cooler, while darker colors absorb heat, which can be useful in cooler climates. Color markings also help identify wrap orientation and end-of-roll indicators during operation. XES® net wraps include clear side markings and red end-of-roll signals for easier handling and efficient workflow.