How long does a hay bale last?

How long does a hay bale last before losing value? Learn the real-life spans of hay storage and proven ways hay sellers can protect quality and profits for longer.

Preface

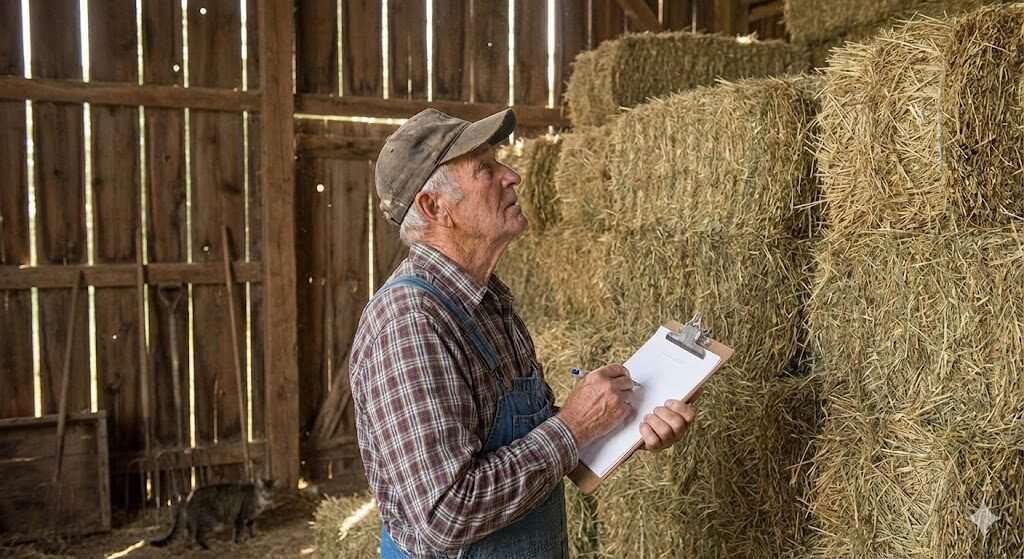

Did you just open a new stack only to realize some bales no longer meet selling quality? Maybe the color faded, mold crept in, or buyers are pushing back on price. As a hay seller, this means lost revenue, damaged trust, and wasted feed. But the truth is simple. Hay doesn’t suddenly fail overnight! It degrades quietly when storage and wrapping fall short. If you are curious to know how long hay is good for and how to protect its value longer, this is your guide. Let’s begin.

How long does a bale of hay last on average?

On average, a well-made hay bale can last 2 to 3 years or longer as long as its storage conditions allow. If you want to store bales correctly, you must understand that hay is a dry product, but it behaves like a sponge. Moisture, airflow, and surface protection determine whether a bale holds value or breaks down.

Dry, tight bales shed water and resist spoilage. Poorly wrapped bales trap moisture and speed decay. Ground contact and rain exposure accelerate hay losses. Climate also matters. For sellers, a bale that lasts 3 years on paper may remain sellable for only 1. Most hay buyers judge bales on appearance, smell, structure, and clean handling.

What is the lifespan for wrapped vs unwrapped hay bales?

Once you understand how long a hay bale lasts on average, the next factor that truly determines longevity is how the bale is wrapped. Bale wrapping controls surface tension, moisture exposure, and structural stability, all of which directly affect a hay bale’s lifespan and resale quality. But not all wrapping methods protect hay equally. Here’s how the most common options compare:

- Net-wrapped hay bales

Net-wrapped bales offer improved surface coverage and tighter structure, lasting 18-36 months indoors and 9-18 months outdoors under proper storage. The net sheds water, limits air entry, and preserves the bale shape. It is ideal for commercial hay sellers who store or transport bales.

- Plastic film-wrapped bales (silage)

Plastic film-wrapped bales can last 24-36 months or longer when sealed correctly. The airtight environment prevents oxygen exposure and preserves forage through fermentation. It is best suited for silage production rather than dry hay intended for open-market resale.

- Twine-wrapped hay bales

Twine-wrapped bales provide minimal surface protection, lasting roughly 18-36 months indoors and about 9-18 months outdoors. Its leaves exposed hay on the bale surfaces, allowing moisture and air to penetrate, causing shape loss and faster deterioration. This method suits short-term covered storage or hay bales intended for immediate use, not resale.

Tip: If you sell dry hay, net wrap offers the best balance between cost, handling efficiency, and even an extended shelf life.

How to tell if a hay bale is bad?

Do you know that even when hay is stored carefully, degradation can still occur over time? Hay rarely spoils without warning, which is why sellers must recognize early signs of quality loss to protect pricing, contracts, and buyer trust.

- Moldy appearance and/or smell

One way to tell bad hay is to look for visible white, grey, or black mold, along with a musty or sour smell. They all indicate excess moisture exposure. Moldy hay loses feed value, risks rejection by buyers, and should never be sold as quality forage.

- Very dusty bales

You can also tell spoiled hay by its excess dust. Dust signals the breakdown of plant structure, often caused by over-drying or prolonged exposure to air and sunlight. Dusty hay appears old, handles poorly, and is commonly discounted or refused by buyers.

- Lack of color

Hay that appears grey, brown, or faded has likely suffered from UV exposure or moisture damage. Loss of natural green color reduces nutritional appeal and market value, even if the bale remains physically intact.

Common mistakes that shorten hay bale lifespan

Most hay spoilage traces back to avoidable handling and storage errors. These mistakes quietly reduce bale value long before sale. Some common mistakes include:

- Baling at incorrect moisture levels: Hay baled too wet traps moisture and molds quickly. Hay baled too dry shatters leaves, reducing feed value and sale appeal.

- Using a low-quality bale wrap: Weak wrap loosens early. Air enters. Moisture follows. Bale shape collapses during handling and stacking for storage or transportation.

- Poor stacking and ground exposure: Bales placed directly on the soil absorb ground moisture. Bottom layers spoil first, often unseen until sale time or when buyers are inspecting the stacks.

- Ignoring climate factors: Rain, humidity, and UV exposure vary by region. Hay storage methods that work in one area, such as Europe, may fail in another area, like Australia, without adjustments.

How to extend the life of hay bales for sale

If you want to keep hay bales in sellable condition, storage discipline matters. This becomes critical for long-term holding. Small improvements protect quality, reduce losses, and preserve buyer confidence over time. Here are a few tips:

#Use high-quality hay net wrap

Strong, consistent net wrap maintains bale tension, sheds water, and limits airflow. It offers proper hay coverage that protects edges, reduces spoilage, and keeps bales sellable. Each bale remains firm and presentable through handling, storage, and transport.

a. XES® Classic Bale Net Wrap

XES® Classic suits everyday hay sellers who need dependable performance without premium pricing. It maintains hay bale shape, resists early loosening, and supports longer storage while keeping cost per bale predictable.

Key features

- Knitted chain structure: Maintains consistent tension across the net, helping bales hold shape during stacking, transport, and longer storage periods.

- Universal baler compatibility: Feeds smoothly through major round baler brands, reducing setup issues and preventing uneven wrapping or feeding interruptions.

- Guaranteed extra length: Provides predictable footage per roll, allowing sellers to calculate cost per bale accurately and avoid unexpected roll shortages.

- Clean edge coverage: Wraps bale shoulders tightly, limiting moisture entry at vulnerable edges where spoilage often begins.

- Even winding: Supports steady net release, reducing stops, misfeeds, and wasted time during long baling days.

- Clear roll markings: Help operators load rolls correctly and monitor wrap alignment throughout the baling process.

b. XES® Extreme Bale Net Wrap

XES® Extreme is built for dense crops and demanding conditions. It resists tearing under pressure and supports sellers who store bales outdoors or move heavy loads across longer distances.

Key features

- Reinforced threads: Strengthened fibers handle dense silage, maize, and heavy straw without tearing or stretching unevenly.

- High tensile strength: Maintains bale stability under compression, stacking pressure, and repeated handling.

- UV resistance: Slows material breakdown caused by sunlight during outdoor storage periods.

- Guaranteed roll length: Ensures reliable bale counts per roll for planning labor, inventory, and costs.

- Smooth surface: Promotes fast, even wrapping while reducing drag inside the baler.

- Strong edge hold: Secures bale shoulders tightly, limiting moisture penetration at the most exposed points.

c. XES® Supreme Bale Net Wrap

XES® Supreme supports high-volume operations where downtime affects profit. Longer footage per roll reduces changeovers while maintaining strength for tight bale density and demanding crops.

Key features

- Advanced thread structure: Distributes tension evenly across the net to reduce stress points and tearing.

- Extended roll footage: Produces more bales per roll, cutting roll changes and labor interruptions.

- Flat surface finish: Reduces friction inside balers, helping limit wear on machine components.

- High tensile performance: Handles heavy, dense bales without losing shape or strength.

- Consistent manufacturing: Delivers uniform quality across large volumes for cooperatives and multi-site farms.

- Reliable edge coverage: Protects bale edges from moisture intrusion, preserving structure during extended storage.

#Bale hay tightly

Dense bales shed water more effectively and allow less air movement. Proper baler tension reduces internal moisture pockets, limits spoilage risk, and keeps bales firm during stacking, transport, and long-term storage.

#Don’t put hay bales in direct contact with the ground during storage

Soil transfers moisture into bales through capillary action. Using pallets, gravel bases, or tires helps lift bales off the ground, protecting the bottom layers and preventing hidden spoilage that only becomes apparent at sale time.

#Provide overhead cover, especially for outdoor storage

Roofed storage or secured tarps block rainfall and UV exposure. Even partial cover slows weather damage, preserves color and structure, and helps outdoor-stored bales remain sellable for longer periods.

FAQ

- Does hay ever go bad?

Yes. Hay absolutely goes bad. This happens primarily by losing nutritional value and developing mold if stored improperly with moisture, heat, and poor ventilation. However, if well-stored, hay can last years, but with reduced vitamins from 6 months onwards. Key indicators of spoiled hay are a musty smell, gray color, and dampness. If you want to store your hay for a long time, use plastic net wrap rolls like XES bale nets to cover your bales.

- Is a 1-year-old hay bale still good?

Yes, a 1-year-old hay bale can still be good for feeding livestock like horses or cattle, provided it was stored dry and properly. It will also have lost crucial vitamins such as the beta-carotene for Vitamin A, and may be dustier. Before selling, it is good to first inspect it for mold, dust, and mustiness. To know if the hay is still usable, check for a decent smell and a lack of mold. To keep your bales in perfect conditions, use XES bale net wraps.

- How long is hay good for when stored outdoors?

Unprotected outdoor hay can spoil in days to weeks. However, with proper outdoor bale storage (covered with a tarp, elevated on pallets/gravel), it can last several months to over a year. The hay quality and vitamins decline, with losses increasing significantly after 9-12 months. The key is keeping it dry, off the ground, and protected from rain, sun, and excessive moisture. Use XES bale net wraps to ensure the bales keep their shape and rigidity.

- Does net wrap extend hay bale lifespan?

Yes, net wrap significantly extends hay bale lifespan. It protects it from moisture, sun (UV), and pests, keeping it in a stable shape for longer storage, especially outdoors. This protection means net-wrapped bales can last weeks or months outside, or years indoors. You need high-quality net wraps like the XES bale net wraps to have sellable bales in your barn for longer.

- What causes hay bales to spoil the fastest?

Hay bales spoil fastest due to high moisture content from rain or humidity and poor storage, such as ground contact and no airflow. These can lead to mold, nutrient loss, and dangerous heat buildup that can even cause spontaneous combustion. Exposure to elements such as UV light, stacking too tightly, and baling too wet can also fasten spoilage. One of the ways to keep your bales secure and prevent such problems is to wrap them with XES bale net rolls.

- How can sellers prevent mold in hay bales?

Sellers can prevent mold in hay bales through proper harvesting at the correct moisture levels, adequate curing, and strategic storage techniques that ensure good air circulation. It is good to always use precautionary measures, such as correct net wrapping. XES Bale Net offers the best wrapping solutions to protect your hay bales for longer.

- Are wrapped hay bales better for long-term storage?

Yes, wrapped hay bales are better for long-term storage when stored outdoors compared to unwrapped bales. The wrapping significantly reduces dry matter and nutrient loss due to weather exposure. One of the best ways to wrap hay bales is to use plastic net rolls such as the XES® Supreme Bale Net wrap.

Conclusion

So, how long does a hay bale last? As long as your storage and wrapping allow it to stay sellable. For hay sellers, lifespan equals value. Strong net wrap, proper baling, and smart storage protect that value season after season. If you want to reduce hay losses and extend bale life, explore premium-quality net wrap solutions at xesbalenet.com and protect every bale you plan to sell.