How much does a bale of hay weigh?

Meta description: How much does a bale of hay weigh? Learn the weights of square and round bales, why it matters, and how sellers can ensure consistency and value with the right wrapping solutions.

Preface

For many farmers, hay is money in the barn. But when bale weights vary wildly, profits slip away, storage becomes a gamble, and feeding livestock turns into guesswork. Too light, and buyers feel shortchanged. Too heavy, and handling costs skyrocket. This guide cuts through the confusion. Read on to learn exactly how much different bales weigh, what affects their weight, and how to keep every load consistent.

What is a bale of hay?

A bale of hay is a compact bundle of dried forage, designed for storage, transport, and feeding. It can be made from grass species like timothy or Bermuda, legumes such as alfalfa and clover, cereal grain crops, or mixed varieties. Each bale type brings its own nutritional value and market demand.

Different types of hay bales

Hay bales are produced in two main shapes: round and square, each targeting different farm needs. Square bales are usually smaller in size, measuring about 2ft by 2ft by 3-4ft. They sell in small portions for small farms and individual feeding. Large square bales measure around 3ft by 3ft by 8ft or 4ft by 4ft by 8 ft, and are common on large farms and commercial operations. On the other hand, round bales can also be small, measuring about 4 ft in diameter and 4-5ft wide, or large, measuring 5-6ft in diameter and 4-5ft wide. Round hay bales dominate commercial operations thanks to lower labor costs and ease of feeding livestock.

How much does a bale of hay weigh?

Different hay bales have varying weights depending on the bale size, density, and hay type. On average, a small square bale’s weight can range from 40 to 60 pounds, which you can handle by hand. Large square bales can weigh between 800 and 1500 pounds and require machinery for easy handling. As for round bales, a small one can weigh from 500 to 700 pounds, while a large round bale can weigh between 1200 and 2000 pounds. This wide variation means sellers must know their bale type before setting prices or planning transport.

● How much does a rectangular hay bale weigh?

Rectangular bales are widely used in small- to mid-sized operations. Their weight varies by size and string count.

| Size | Dimension (L x H x W) | Weight |

| 2-stringed bales | 36” x 19” x 16” | 40 to 75 lbs |

| 3-stringed bales | 44” x 22” x 15” | 100 to 140 lbs |

| Half ton | 6ft x 4ft x 3ft | 1000 lbs |

| 1 Ton | 8ft x 4ft x 4ft | 2000 lbs |

● How much does a round bale of hay weigh?

Round bales are more common in large-scale farming due to efficiency in production and feeding.

| Size | Dimension (Width x Height) | Weight |

| Small | 4 ft x 4 ft | 400 to 600 lbs |

| Medium | 5 ft x 4.5 ft | 720 to 950 lbs |

| Large | 5 ft x 6 ft | 1270 to 1700 lbs |

What affects the weight of hay bales?

Bale weight isn’t fixed. It shifts depending on factors sellers must monitor, from plant type to storage time. Understanding these variables helps you manage inventory, set fair prices, and maximize profit.

- Plant varieties: Legume hay, like alfalfa, is denser and heavier than grass hay, making it ideal for premium buyers who need high-protein feed. Sellers can price legumes higher while offering grass hay for cost-conscious livestock owners.

- Moisture content: Freshly baled hay carries more water, so it’s heavier. Sellers should track moisture before pricing since overcharging for water weight risks customer trust, while managing moisture prevents spoilage and waste in storage.

- Bale density: Tighter wrapping creates heavier, more compact bales that save space and reduce shipping costs. For sellers, this means more efficient transport and the ability to deliver consistent quality to repeat buyers.

- Maturity at harvest: Overripe hay can be stem-heavy and less dense, lowering feed quality. Sellers who harvest at the right time can command premium prices and build a reputation for reliable, nutrient-rich hay.

- Time of sale: Stored hay gradually loses moisture, becoming lighter. Weighing bales closer to sale helps sellers set accurate prices, avoid disputes, and maintain strong relationships with repeat customers.

- Model of baler used: Equipment settings affect compression and final bale weight. Sellers using modern balers can produce consistent bales, streamline inventory, and attract bulk buyers who prefer uniform, predictable loads.

How to weigh a bale of hay

Weighing a hay bale isn’t complicated, but accuracy matters if you want fair pricing and reliable weight records. Small hay bales can be measured on basic scales, while larger ones need stronger equipment. Here’s how to do it for different scenarios:

- Small bales – Use a bathroom scale or portable livestock scale. Place the bale carefully in the center and check the reading. Balance matters for accuracy.

- Large bales – Use a heavy-duty platform scale. Roll or lift the bale onto the platform with machinery and record the weight. These scales handle heavy loads with ease.

- Estimation method – If you don’t have a scale, measure the bale’s dimensions and compare with standard averages for that bale type. This gives a rough but useful estimate.

- Bale spear with scale – Some tractors come with a spear that includes a built-in scale. It won’t be as precise as a platform scale, but it’s quick and practical for bulk loads.

- Record the weight – Track the weight by bale size and type, then average multiple readings. This ensures reliable data for calculating price per ton and keeps buyers confident in your numbers.

Why does the weight of hay bales matter?

Accurate bale weights protect sellers from undervaluing or overselling their hay. For farmers and buyers, it ensures fair pricing, efficient operations, and better outcomes for livestock.

- Cost efficiency: Prices are calculated per ton, so knowing the exact weight of each bale helps sellers set accurate prices, avoid revenue loss, and guarantee buyers get full value for their purchase.

- Preventing waste: Bales that are wrapped tightly and uniformly maintain their shape and moisture balance, reducing spoilage and shrinkage during storage. This protects both profits and feed quality.

- Transport & storage: Heavy bales require stronger handling equipment, trailers, and storage structures. Accurate weight records allow sellers and buyers to plan logistics safely and prevent costly damage or inefficiencies.

- Feeding accuracy: Livestock nutrition depends on consistent rations. Standardized bale weights make it easier to calculate daily feed portions, improving animal health while preventing both underfeeding and unnecessary waste.

The simplest way to achieve consistent bale weights, while saving time, money, and feed quality, is to use durable bale net wraps that keep every bale tight, uniform, and reliable.

Where to get reliable bale net wraps for consistent weights

The best way to secure consistent bale weights, reduce waste, and protect your harvest is with XES® Bale Net Wrap. For over 20 years, XES® has been a trusted partner for European, US, and Australian farmers. The company is popular for delivering durable, eco-friendly net wraps designed to keep hay bales tight, uniform, and ready for storage or transport. Whether you need dependable standard performance or cutting-edge efficiency, XES® has a solution.

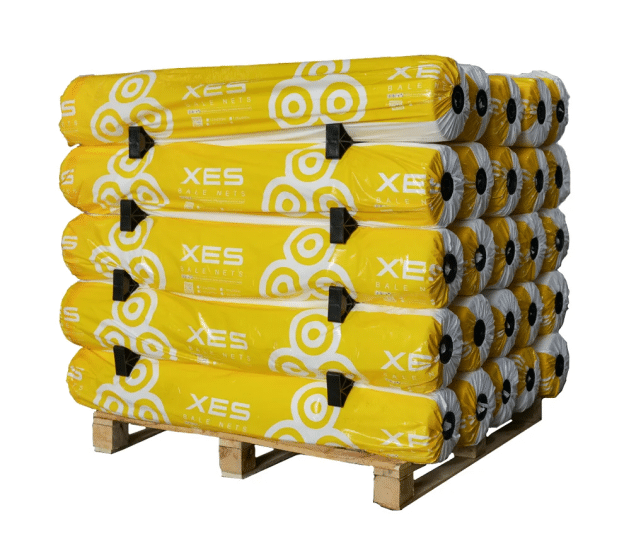

1. XES® Classic Bale Net Wrap

The Classic is the reliable all-rounder, a base version that already guarantees impressive quality. It is built from eco-friendly HDPE that combines solid strength, UV protection, and smooth application. Moreover, it is designed to work with all popular round balers. This helps hay bale sellers reduce downtime and keep baling efficient.

Key features

- Classic strength: Knitted chain structure with reinforced threads, ensuring durability and less waste.

- Universal fit: Works with leading round balers, including John Deere, New Holland, and Vermeer.

- Guaranteed length: Every roll delivers exactly what’s promised, plus an extra 150 ft for added value.

- Smart markings: Side markers and a red end-of-roll signal streamline the baling process.

- Neat and even: Precisely edged and wound for smooth handling and less waste.

- UV protection: Stable for at least 12 months in Central European conditions.

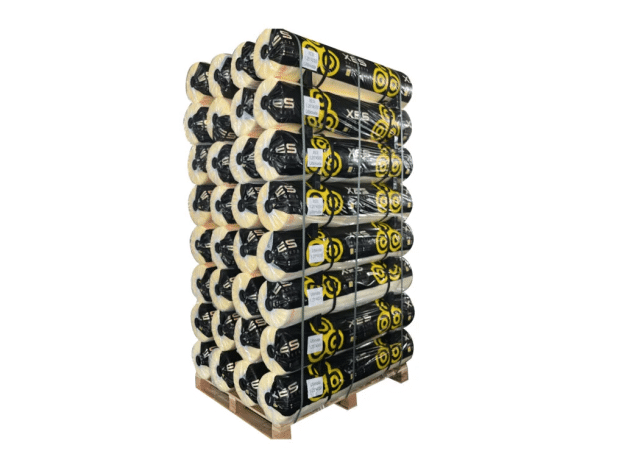

1. XES® Extreme Bale Net Wrap

For demanding conditions, the Extreme offers premium durability backed by DLG certification, a hallmark of quality from the German Agricultural Society. Designed for heavy materials and tougher baling jobs, it ensures strength, efficiency, and reliability in every roll.

Key features

- DLG-certified: Tested and approved by the German Agricultural Society for proven performance.

- Extreme strength: Reinforced knitted chain structure recommended for 2.25-2.5 wraps per bale.

- Universal fit: Compatible with all major balers, including John Deere, New Holland, and Vermeer.

- Guaranteed length: Extra 150 ft per roll, ensuring consistent value.

- Smart markings: Side color codes and red end-of-roll marker improve efficiency in the field.

- Eco-friendly and durable: Made from HDPE with 12-month UV stability and tube packaging for added protection.

1. XES® Supreme Bale Net Wrap

The Supreme represents next-level innovation with patented weaving technology that connects one warp thread to three weft threads. This creates a smoother surface, distributes weight evenly, resists sun exposure, and significantly boosts efficiency. With up to 5,000 meters per roll, farmers get more wrap without increasing roll size.

Key features

- Patented technology: Unique structure increases tear resistance and reduces machine wear.

- High strength: Tensile resistance of up to 300 kg for heavy-duty tasks like corn harvesting.

- Maximum efficiency: Longer rolls (up to 5,000 m) mean fewer changes, less downtime, and faster operations.

- Universal fit: Runs smoothly on all established baling machines.

- Eco-friendly HDPE: Strong, recyclable material designed for performance and sustainability.

- UV protection: Guaranteed stability for at least 12 months in Central Europe.

FAQ

- How much does a bale of hay weigh in kg?

A bale of hay can weigh anywhere from 18 to 900 kilograms, depending on size, shape, and density. Small square bales are light enough to handle manually, while large round or square bales need machinery. To keep bale weights consistent, farmers trust XES® Bale Net Wrap for premium quality, performance, and durability.

- Is it better to have heavy or light hay bales?

Neither is inherently better. It depends on your needs. Heavy bales are efficient for large-scale operations, while lighter ones are easier to handle on smaller farms or individual livestock. What matters most is uniform density, which XES® Bale Net Wrap delivers to ensure reliable weights across every bale.

- How are hay bales so heavy?

Hay bales are heavy because they are tightly compacted with layers of dried forage. Density, moisture, and baler settings all increase the final weight. Without consistent wrapping, bales can lose shape or density. XES® Bale Net Wrap helps maintain even compaction, ensuring bales stay secure, uniform, and easier to transport.

- How much do small hay bales weigh?

Small square hay bales typically weigh between 18 and 27 kilograms (40-60 pounds). They are manageable by hand, making them popular on smaller farms and for individual feeding. To reduce spoilage and maintain consistent weight, many farmers choose XES® Classic Bale Net Wrap for dependable results.

- How much do large square hay bales weigh?

Large square bales generally weigh between 360 and 900 kilograms (800-2,000 pounds), depending on dimensions and density. These require machinery for handling and transport. For reliable weight and longer storage life, XES® Supreme Bale Net Wrap ensures these heavy bales are secured with maximum durability.

- How much is a full load of hay?

A standard semi-truck or flatbed trailer can haul a full load of hay, usually 48,000 to 50,000 pounds (about 21,800-22,700 kilograms). The total depends on bale size and density. For safer stacking and transport, XES® Bale Net Wrap keeps bales secure, uniform, and easier to handle in bulk.

Conclusion

Hay bale weight is never just a random number. It impacts pricing, storage, transport, and animal nutrition. Farmers and hay sellers who prioritize consistency protect both profits and livestock health. The most reliable way to achieve uniform bale weights is with XES® Bale Net Wrap, trusted across Europe for strength, efficiency, and eco-friendly performance. Ready to secure your harvest? Explore XES® Bale Net Wrap solutions today!