What are hay bales used for?

What are hay bales used for? Discover 10 practical, profitable uses of hay bales and learn how sellers protect value, expand markets, and reduce losses.

Preface

Every hay bale leaves the field with a price tag already attached to it. This is not only because of the crop inside, but also because of how the bale was made, packed, and prepared. Do you know that many farms lose value before the bale is even sold? Yes. The reason? They treat all bales the same or aim for the wrong outcome! Bales serve far more purposes than most sellers plan for, and each purpose carries a different value. Knowing what a bale is capable of gives you a clear advantage. This article shows where profit is created and where it quietly slips away. Let’s begin.

What are hay bales?

Hay bales are tightly compressed bundles of dried forage crops such as grass, alfalfa, or clover. After cutting and drying, the forage is pressed and secured using twine or bale net wrap to form a stable unit for easy storage, handling, and hauling. The most common types are round bales and square bales. Bale type matters. It affects how bales are wrapped, stacked, transported, and sold. For sellers, the right bale format improves efficiency and resale flexibility. Moreover, shape and density also affect how well a bale performs across different end uses.

What are hay bales used for? 10 Most common uses revealed

Hay bales extend far beyond basic farm use. They are used in agriculture, creative projects, commercial operations, and many practical applications. Each usage places different demands on bale quality, shape, and presentation. Below are the most popular bale uses:

1. Livestock feeds

Hay bales serve as a primary feed source for cattle, horses, and sheep. They supply fiber and essential nutrients. Dense, well-dried round bales or uniform square bales are preferred. The best-quality hay feed has clean color, tight wrapping, and minimal leaf loss.

2. Long-term feed storage

Another use of hay bales is to make silage, a fermented animal feed stored for a long time. It uses round bales wrapped with net rolls, plastic films, or both. High density, even shape, and strong edge protection reduce moisture entry. Proper presentation ensures the bale remains marketable months later, especially when stored outdoors or transported long distances.

3. Bedding and animal comfort

Lower-grade hay bales are widely used for bedding in cattle sheds, horse stalls, and poultry houses. Square bales are easier to break apart and spread evenly. Dry, mold-free presentation matters more than nutritional quality, making consistent bale formation important for resale.

4. Mulch in gardens and flower beds

Hay bales are used as mulch to retain moisture and suppress weeds in gardens and landscaping projects. Small square bales are preferred for handling and placement. Clean, seed-free hay with a tidy appearance improves usability and broadens non-farm sales opportunities.

5. Erosion control and land management

Hay bales help stabilize soil on slopes, at construction sites, and along waterways. Round or square bales with firm structure resist collapse when exposed to rain. Presentation focuses on tight bale binding and durability rather than feed quality. This allows sellers to move surplus or lower-grade hay bale stock.

6. Biomass resource in sustainable farming

In sustainable systems, hay bales supply biomass for composting, soil conditioning, and energy production. Large round bales with consistent density are preferred for mechanical handling. Even shape and secure wrapping reduce losses during transport and processing across industrial or cooperative operations.

7. Egg cushion for layer operations

Poultry farms use hay bales as cushioning in egg collection areas to reduce breakage. Small square bales are preferred by most for controlled placement. Clean, dry hay with tight binding prevents dust and contamination, making bale presentation a key factor for repeat buyers.

8. Photography props and decorative uses

Hay bales appear in seasonal displays, such as Christmas decorations, farm branding, and photo shoots. Square, dried bales with sharp edges and uniform color sell best. Clean bale wraps and neat stacking protect visual appeal. That way, sellers can access higher-margin non-agricultural markets.

9. Art, craft, and community projects

Artists and community groups use hay bales for installations, festivals, and public events. Lightweight square bales are easier to move and shape. Consistent size, tidy appearance, and secure binding help sellers meet visual standards while moving inventory beyond farm channels.

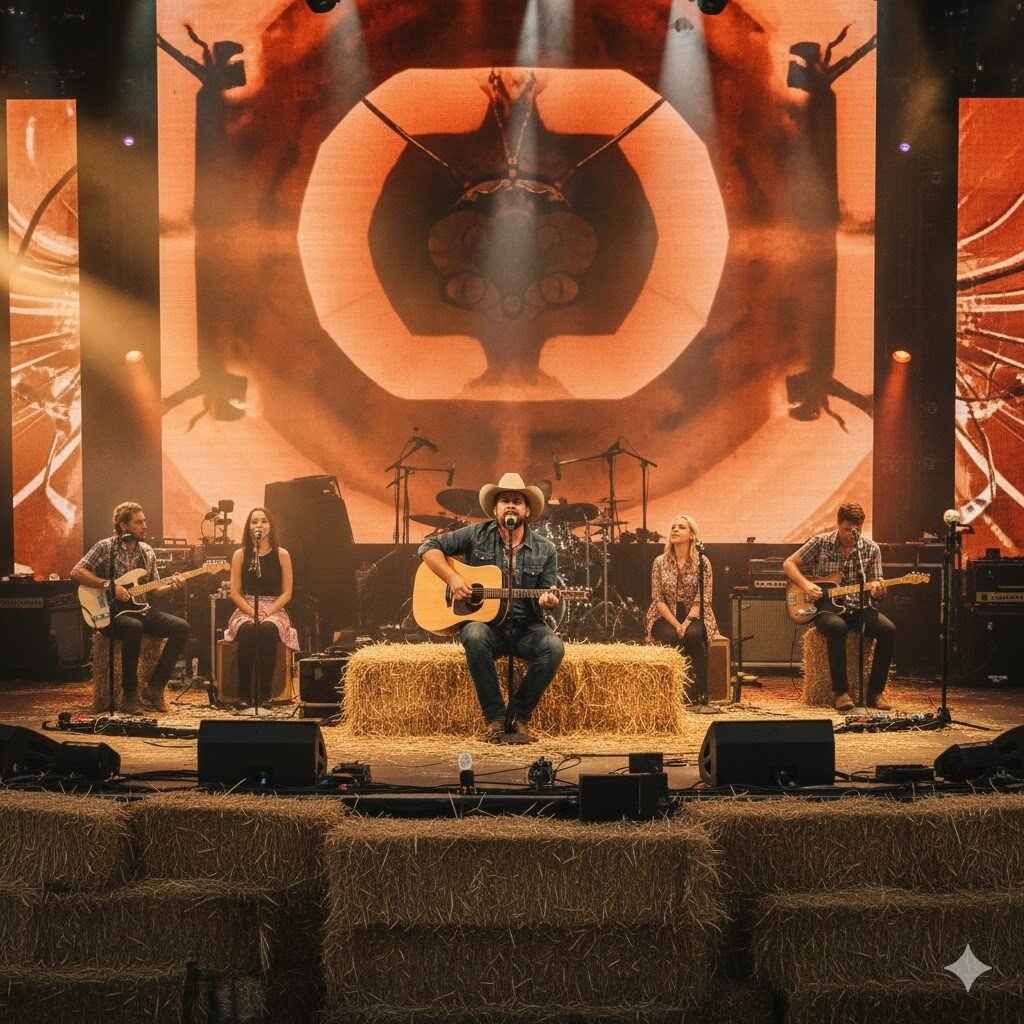

10. Music, theatre, and stage settings

Hay bales feature in stage design for concerts, plays, and themed events. Square bales dominate due to their symmetry and ease of stacking. Here, presentation matters more than feed value. It should have clean surfaces, firm edges, and reliable binding. This ensures it supports safe bale handling and professional stage setups.

How to store hay bales?

Hay storage determines how many of these uses remain open to sellers and how long bales hold value after baling. Good bale storage protects shape, limits spoilage, and preserves flexibility. So, whether bales go under a roof or stay in the open, proper wrapping and handling set the ideal foundation for long-term quality.

- How to store hay bales indoors

Indoor storage involves placing bales inside barns, sheds, or covered storage facilities. To store hay properly, you need controlled airflow and a dry, raised floor. This method suits commercial hay sellers, dairy operations, and cooperatives in high-rainfall regions or those selling premium feed hay. Indoor-stored hay often targets feed, export, and long-term contracts.

- How to store hay bales outdoors

Outdoor storage places bales in open yards or fields, usually on raised ground, gravel pads, or old tires. It relies on elevation, drainage, quality wrapping, and a top protective cover. It suits large-volume sellers, dry climates, or overflow storage. Hay stored outdoors is commonly sold to beef operations, seasonal feeders, or long-distance transporters. Here, durability matters more than appearance.

Packaging and wrapping for different uses of hay bales

Not all hay bales need the same level of protection, however, hay sellers can have lots at stake if you underpackage your hay. Feed and export bales demand strong, consistent wrapping. This protects bale quality, shape, and moisture resistance. Non-feed hay uses may tolerate lower standards, yet poor packaging permanently caps a bale’s resale value. Smart sellers package bales to meet the highest-value potential use, keeping more markets open for longer.

Does net wrap help expand the uses of hay bales?

Yes. Net wrap directly increases the number of end uses a bale qualifies for. By holding bale shape tightly, protecting vulnerable edges, and improving weather resistance, net wrap keeps bales intact during storage, hauling, and handling. Well-wrapped bales remain suitable for feed, long-term storage, transport logistics, and export preparation. Without proper net wraps, many of these markets disappear before buyers even inspect the bale.

What is the best net wrap solution for multiple hay bale uses?

XES® Bale Net is among the leading net wrap suppliers serving farms and cooperatives across Europe and Australia. We operate on a direct manufacturer-to-you model, removing middlemen and inflated margins. This allows hay bale sellers to access reliable, consistent net wrap rolls at pocket-friendly prices. Our bale netting maintains the ideal strength and performance required for multi-use hay bale markets. Below are our net wrap products:

a. XES® Classic Bale Net Wrap

XES® Classic is designed for everyday hay sellers who need dependable performance across multiple bale uses. It maintains bale shape, feeds smoothly through balers, and delivers predictable roll length for consistent cost control and reliable storage results.

Key features

- Knitted chain structure: Maintains uniform tension across the net, helping bales hold shape during stacking, handling, transport, and extended storage without premature loosening.

- Universal baler compatibility: Designed to feed smoothly through all major round baler brands, reducing setup time, misfeeds, and uneven wrapping during busy baling operations.

- Guaranteed roll length: Delivers consistent footage per roll, allowing sellers to accurately calculate cost per bale and plan inventory without unexpected shortages.

- Clean edge coverage: Wraps bale shoulders firmly, limiting moisture penetration at the edges where spoilage and breakdown commonly begin.

- Even winding: Ensures smooth net release during wrapping, reducing stops, operator frustration, and wasted time during long baling days.

- Clear roll markings: Help operators load rolls correctly and monitor wrap alignment, improving consistency across large bale runs.

Common uses of XES® Classic:

Livestock feed, bedding, indoor storage, short-term outdoor storage, mulch, and community projects.

b. XES® Extreme Bale Net Wrap

XES® Extreme is built for dense crops, heavy handling, and demanding outdoor conditions. It resists tearing under pressure and supports sellers who store bales outside or transport heavy loads over long distances.

Key features

- Reinforced threads: Strengthened fibers handle dense silage, maize, and heavy straw without tearing or stretching unevenly under pressure.

- High tensile strength: Maintains bale stability during compression, stacking, repeated handling, and long-distance transport.

- UV resistance: Slows material degradation caused by prolonged sunlight exposure during outdoor storage periods.

- Guaranteed roll length: Ensures reliable bale counts per roll, supporting accurate labor planning and cost management.

- Smooth surface finish: Promotes fast, even wrapping while reducing drag inside the baler chamber.

- Strong edge hold: Secures bale shoulders tightly, limiting moisture entry at the most exposed points.

Common uses of XES® Extreme:

Outdoor feed storage, beef operations, long-distance transport, erosion control, export staging, and biomass handling.

c. XES® Supreme Bale Net Wrap

XES® Supreme is engineered for high-volume operations where downtime directly impacts profit. Extended footage per roll reduces changeovers while maintaining strength for tight bale density and demanding crop applications.

Key features

- Advanced thread structure: Distributes tension evenly across the net, reducing stress points and improving tear resistance under heavy loads.

- Extended roll footage: Produces more bales per roll, reducing roll changes and improving baling efficiency.

- Flat surface finish: Lowers friction inside balers, helping reduce wear on belts, rollers, and net feed systems.

- High tensile performance: Handles heavy, dense bales without compromising structure or wrap integrity.

- Consistent manufacturing: Delivers uniform quality across large volumes, supporting cooperative and multi-site supply needs.

- Reliable edge coverage: Protects bale edges from moisture intrusion during long-term storage and repeated handling.

Common uses of XES® Supreme:

Premium feed, export hay, long-term storage, high-output cooperatives, silage handling, and commercial transport supply chains.

How can hay sellers increase profit by matching bale use?

Hay bales earn more when they are made with a clear purpose from the start. When quality, wrapping, and storage match the intended use, sellers reduce losses and gain stronger control over pricing. Here’s how to do it:

- Producing bales for specific markets

Decide early whether the hay is for feed, bedding, export, biomass, etc. This choice guides bale density, wrap strength, and storage method. It is crucial because it helps you easily meet buyer expectations without over- or under-producing.

- Reducing waste through better packaging

Prepare your bales to be firm and rigid, limit moisture damage, and prevent hay loss during handling and transport. Use strong net wraps consistently for less damage. You will have more sellable bales and fewer discounts.

- Selling more hay at higher grades

Ensure well-packaged bales so they stay clean, firm, and presentable. That allows sellers to access premium markets, move inventory faster, and avoid downgrading hay bales due to preventable quality loss.

FAQ

- What are hay bales mainly used for?

Hay bales are mainly used for livestock feed and long-term forage storage. They are also used for animal bedding, erosion control, biomass, and decorative purposes. Because these uses demand different bale quality levels, sellers benefit from consistent wrapping. With solutions like XES® net wraps, it is effortless to preserve flexibility and value.

- Are hay bales only used for animal feed?

No. While feed is the primary use, hay bales are also used for bedding, mulch, erosion control, composting, and even event staging and props. Clean, well-shaped bales expand resale options, which is why reliable net wrap, like XES Classic, matters beyond feed markets.

- Can the same hay bale be used for different purposes?

Yes, but only if quality is preserved. For example, a hay bale made for feed can later be sold for bedding or biomass if it stays dry and intact. It may also be shifted to erosion control, props, or decorative use if the appearance and structure remain acceptable. For all these uses, proper bale net wrapping, such as XES® Extreme, helps protect bale shape and keeps these options open.

- Why does hay bale packaging matter for end use?

Hay bale sells just like any other commodity, and the right packaging matters a lot. It directly determines the preservation method, the nutritional quality, and the storage, handling, and transportation requirements of the bale. It protects the bale shape, moisture resistance, and cleanliness. Also, feed and export markets demand tighter standards than non-feed uses. Using XES net wrap ensures bales remain suitable for higher-value markets longer, rather than being downgraded early.

- How does net wrap increase hay bale value?

Net wrap improves bale density, edge protection, and weather resistance. This reduces spoilage and handling damage, allowing sellers to store, transport, and market bales with confidence. If you want durable net rolls, choose XES® Bale Net for both indoor and outdoor storage.

- Do hay bale uses differ in regions across the globe?

Yes, hay bales applications vary globally. This is primarily influenced by regional climate, the level of agricultural mechanization, cultural traditions, and local resource availability. While the primary use everywhere is animal fodder, secondary uses and methods vary widely. If you want high-quality bales for multiple uses, always use XES bale net wraps. They keep the bale shape intact from the field to the customer.

- Why do farmers wrap hay?

Farmers wrap hay bales to protect them from the weather, reduce spoilage, create silage through fermentation, and offer flexible storage. Proper wrapping protects hay from moisture, maintains bale shape, and reduces losses during transport. It also improves handling efficiency and resale value. Therefore, quality net wrap, such as the XES Supreme, helps ensure bales meet multiple end-use requirements without added risk.

Conclusion

Hay bales are not just stored forage. They are a sellable product with many possible uses and price points. When sellers match bale type, wrapping, and storage to the right market, they protect value and reduce losses. Strong, consistent net wrapping helps preserve shape, quality, and flexibility. That is why many farms and cooperatives rely on dependable solutions like XES® bale net wraps to keep their bales market-ready longer.